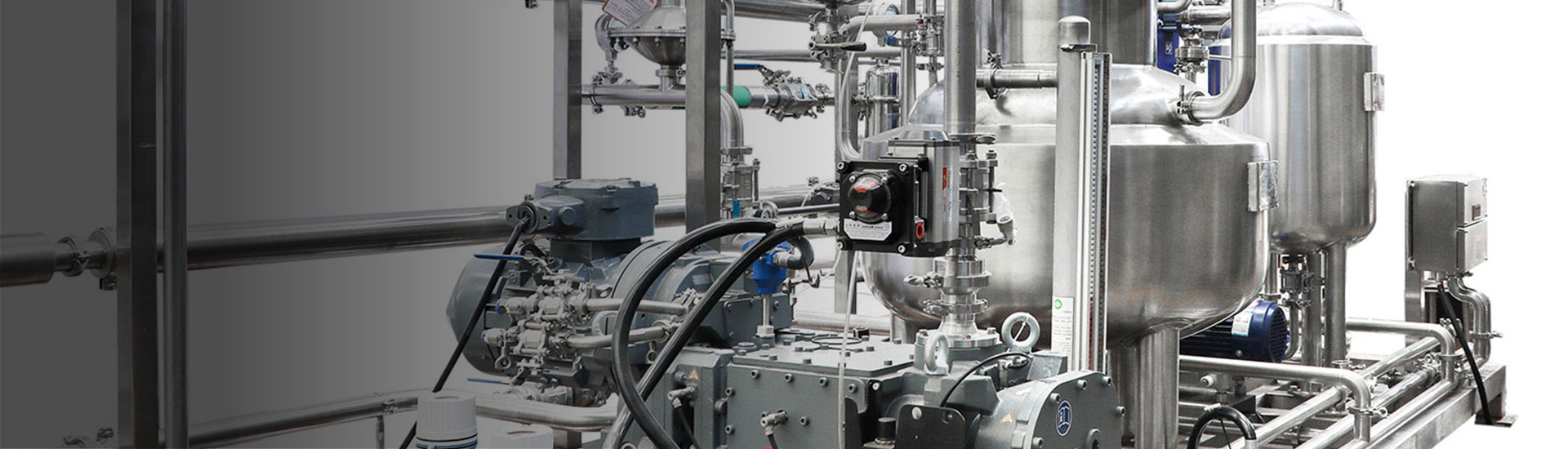

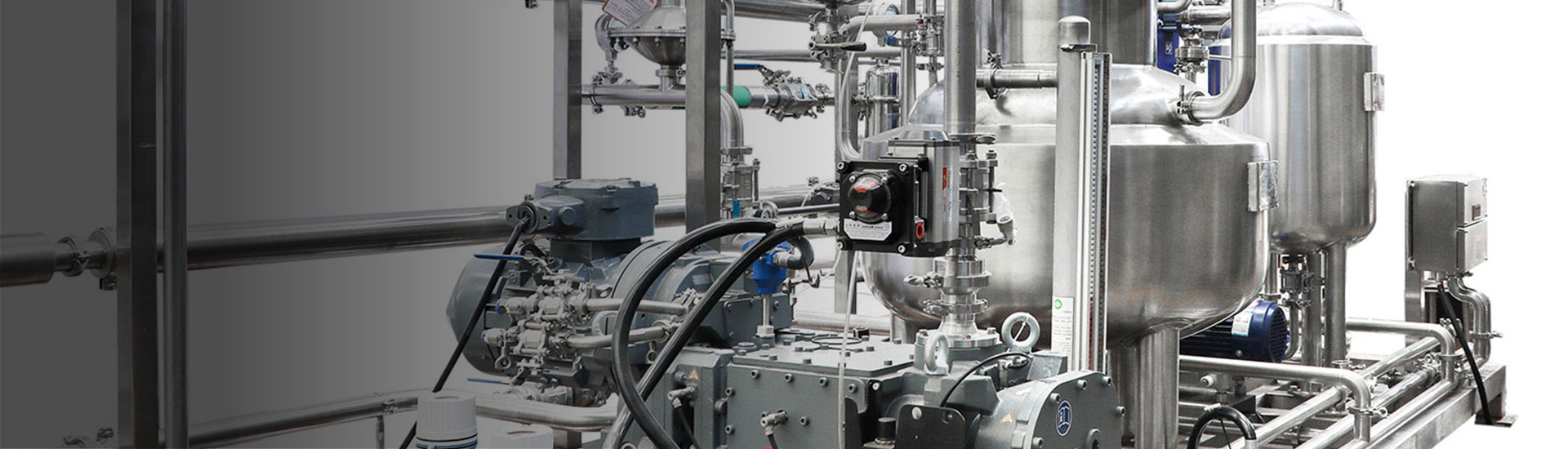

● Heating/cooling components

-Steam, thermal oil, refrigerants

● Circulation pumps

-High-temperature-resistant magnetic drive pumps with variable frequency control

The TCU (Temperature Control Unit) Process Module delivers precise, stable, and rapid-response temperature control for industrial processes. Integrating heating, cooling, circulation, and intelligent regulation, it achieves accurate temperature management from -80°C to +300°C, compliant with GMP, ASME BPE, and ATEX standards for sterile, explosion-proof, and highly corrosive environments.

Temperature fluctuation ≤±0.1°C for crystal polymorphism control or pH stability in bioprocessing

Patented flow channel design enhances heat transfer efficiency, reducing energy use by 35%

Hermetic circulation (magnetic pumps + welded pipelines), (Avoid cross-contamination)

Expandable parallel control for multi-equipment setups

compatible with water, silicone oil, thermal oil, glycol, etc

IoT-enabled remote alerts to minimize downtime

Reactor temperature control, fermenter thermostats (37±0.2°C), low-temperature drug loading for liposome nanoparticles

Fermentation control, multi-stage chocolate tempering

Catalyst synthesis, polymerization

Low-temperature storage of lithium battery electrolytes, rapid cooling for graphene reactors

High Precision:Temperature fluctuation ≤±0.1°C for crystal polymorphism control or pH stability in bioprocessing

Rapid Response & Energy Efficiency:Patented flow channel design enhances heat transfer efficiency, reducing energy use by 35%

Patented flow channel design enhances heat transfer efficiency, reducing energy use by 35%

Expandable parallel control for multi-equipment setups

compatible with water, silicone oil, thermal oil, glycol, etc

IoT-enabled remote alerts to minimize downtime

Tailored heating/cooling power, flow rate, and explosion-proof ratings

Temperature Distribution (TD) and Thermal Penetration (TP) reports (USP<1228>compliant)